hardness test of low carbon steel|carbon steel hardness test : bulk The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

18/11/2023 18h42. Coman comemora com Mbappé após marcar no jogo da França contra Gibraltar, pelas Eliminatórias da Euro Imagem: Franck Fife/AFP. A seleção da França .

{plog:ftitle_list}

21 de jan. de 2024 · Veja também a campanha de Liverpool: Jogos: 20; Vitórias: 13; Empates: 6; Derrotas: 1; Gols marcados: 43; Gols sofridos: 18; Saldo de gols: 25; Com isso, Liverpool tem, em termos de campanha geral, a 1ª posição na tabela de .

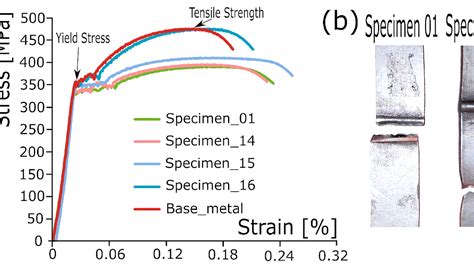

In this study, low-carbon steel was fabricated by 70% rolling with ferrite–pearlite and ferrite–martensite as starting microstructures at liquid nitrogen temperature.

It’s most commonly used to check the hardness of steel that’s been heat treated. Here’s the process: How to Use a Rockwell Testing Machine. Pick out the penetrator. Usually soft materials like 1018 mild steel will use the Rockwell B .Hardness of Low-carbon Steel – ASTM A36. Brinell hardness of low-carbon steel is approximately 120 MPa. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching.

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .

Increased strength, greater hardness, and reduced formability can be imparted in these plain carbon steels as they have carbon content (0.1%0–0.25% C) compared to the lowest carbon group. They are also known as carburizing or casehardening steels by designation. . ASTM A848 is an example of an ultra-low-carbon steel (C .The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters. It is well known that steel gains hardness with an increase in carbon content. On the other side, ductility also gets reduced with increasing carbon amount. Common chemical composition in AISI-1020-0.18% C steel is: carbon (C) = 0.20%; manganese (Mn) = 0.40%; phosphorous (P) ≤ 0.03; sulfur (S) ≤ 0.04 [1, 2]. Heat treating is a thermo .

Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .Hence, for this test, 10 kgf was applied for 15 s to indent on the A333 Grade 6 low carbon steel specimen. The test was repeated on 5 different regions of the specimen, which include 4 edges and a midpoint of the sample. . Meanwhile, the results obtained for A333 Grade 6 low carbon steel show that the hardness value is about 166.826HV. 4.0 .Low-carbon steel contains approximately 0.05–0.25% carbon making it malleable and ductile. Mild steel has a relatively low tensile strength, but it is cheap and easy to form; surface hardness can be increased through carburizing. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for .

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials . In Brinell hardness test, a steel ball of diameter . This was carried out by heating samples of low carbon steel to a specific temperature and then cooling them rapidly in 8 different quenching . Low-carbon steel: AISI 304, ASTM A815, AISI 316L < 0.25: Ferrite, pearlite: Low hardness, high ductility, toughness, machinability and weldability: Medium-carbon steel: . One of the key characteristics of ultra-high carbon steel is its hardness. With a hardness typically above 60 HRC, ultra-high carbon steel is one of the hardest materials .Also hardness ranges for heat treated steel. Online shop Contact. Regional Depots. Bristol: 0117 403 1441 Exeter: 01392 790 275 Inverness: 01463 572 078 Isle of Wight: 01983 640 018 Glasgow: 0141 370 2331 Maidstone: 01622 963 030 Manchester: 0161 641 3700 .

How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . Carbon Steel: Carbon Steel | EN8 | 1.0503 | Fe . shallow case-hardened steel, cemented carbide, other materials with relatively low hardness. HRB: Ø1.588mm Hardened Steel Ball: 980.7 (100) 20-100: Soft metals, non-ferrous metals, annealed .ASTM A36 Steel. ASTM A36 steel is one of the most widely used carbon structural steels, although the carbon content of A36 material is maximum 0.29%, it is considered to be the mild steel (content of carbon ≤ 0.25%).. A36 mild .

what is low carbon steel

With increasing carbon, the hardness and strength of unalloyed steels increases. Above a content of 0.8% C, the strength decreases. As the carbon content increases, the proportion of cementite in the steel also .Low-carbon steel contains approximately 0.05–0.25% carbon making it malleable and ductile. Mild steel has a relatively low tensile strength, but it is cheap and easy to form; surface hardness can be increased through carburizing. Strength of Low-carbon Steel – ASTM A36 The method was done by placing the specimen into a electrolyte solution. Then the hardness test was carried out on the specimen. The results shown that the ST-37 steel coating with nickel with a .Brinell hardness of low-carbon steel . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor .

is the west b test hard

The carbon content in the low-carbon steel is less than 0.25 wt.%. Instead of heat, this carbon steel type is hardened (to form martensite) via cold work. Because of its low strength, this type of carbon steel is relatively soft. Low-carbon steel is an excellent choice for machining owing to its high ductility and cost-effectiveness.SAE AISI 1018 steel is one of the commonly used low carbon steels. It is usually used as carburized steel. . and rockwell hardness. Full Annealing for Small Steel Forgings. AISI 1018 Heat Treatment: Heat Treat: Temperature (℃) Hardness: Cooling/Agent: Section thickness: Annealing (full annealing of small steel forgings) 855-900: 110-150 HB:

This study tested the hardness of aluminum and low-carbon steel using Rockwell hardness testing. Hardness testing measures a material's resistance to plastic deformation by indentation. The study found that low-carbon steel has a higher hardness than aluminum, as steel required greater force to deform its crystal structure. Specifically, the average Rockwell hardness of .

is the west-b test hard

tensile strength of low carbon steel

Low-carbon steel is found in cookware, pipelines, and fencing. Medium carbon steel: Generally contains between 0.31% and 0.6% carbon, plus 0.06% to 1.65% manganese. Stronger than low-carbon steel, but harder to weld, form, or cut. . For applications in which more strength or higher hardness than that of 1008 or 1010 is required. Bolts, gears .The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. . Steel Hardness versus Strength; Brinell Vickers Rockwell Equivalent Rm; Impression Diameter (mm) Hardness HB. Hardness HV. Hardness B. Hardness C (ton f /in 2) (kg f /mm 2) (N/mm 2) 2.50: 601:The connection between hardness and carbon content is clearly visible in the example below: the higher the carbon content, the higher also the HRC of various types of White Steel: White Steel 1 / 63 HRC / C = 1.25-1.35 % White Steel 2 / 61-62 HRC / C = 1.05-1.15 % White Steel 3 / 60 HRC / C = 0.80-0.90 % Measuring hardness There are several .

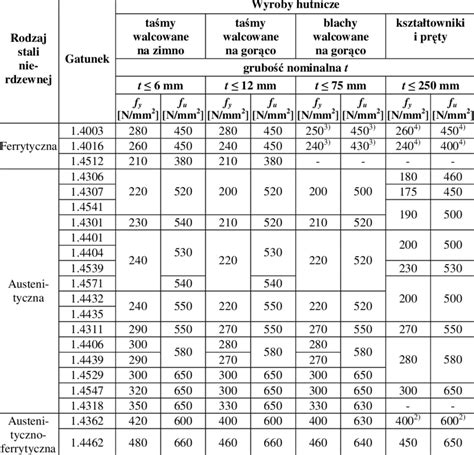

In addition to iron and carbon, stainless steel also adds alloying elements such as chromium and nickel, which have an important influence on the corrosion resistance and hardness of stainless steel. Hardness range: Carbon steels have a wide range of hardness, from low to high. Stainless steels have varying hardnesses, from low for austenite to .

AISI 1095 Steel. SAE AISI 1095 steel is one of the most widely used 10 series steels, with good performance and low cost, with appropriate toughness and wear resistance, but poor corrosion resistance.. 1095 Carbon Steel Applications. AISI SAE 1095 carbon steel can be made into steel billets, steel powder, which can be used as tool steel, blade steel, spring steel. 1095 .

low carbon steel yield strength

Resultado da Guarda i video e gli highlights della Serie A di calcio, con le interviste, le formazioni, le classifiche e le statistiche. Segui le partite, i gol, le polemiche .

hardness test of low carbon steel|carbon steel hardness test